visualcapitalist.com November 15, 2023 By Bruno Venditti

Metals are a big part of our daily lives, found in every building we enter and all devices we use.

Today, major industries that directly consume processed mineral materials contribute 14% of the United States economy.

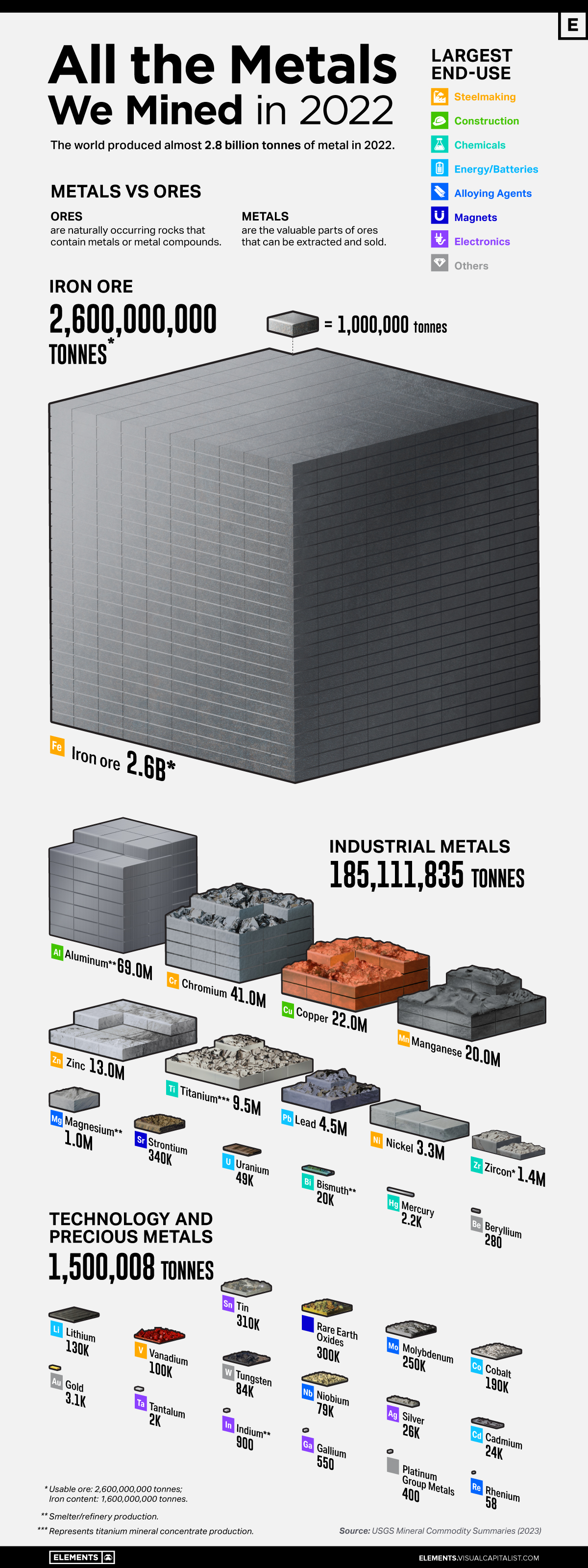

The above infographic visualizes all 2.8 billion tonnes of metals mined in 2022 and highlights each metal’s largest end-use using data from the United States Geological Survey (USGS).

Iron Ore Dominance

Iron ore dominates the metals mining landscape, comprising 93% of the total mined. In 2022, 2.6 billion tonnes of iron ore were mined, containing about 1.6 billion tonnes of iron.

| Metal/Ore | Quantity Mined in 2022 (tonnes) | % of Total |

|---|---|---|

| Iron ore | 2,600,000,000 | 93.3% |

| Industrial metals | 185,111,835 | 6.6% |

| Technology and Precious Metals | 1,500,008 | 0.05% |

| Total | 2,786,611,843 | 100% |

Percentages may not add up to 100 due to rounding.

Iron ores are found in various geologic environments, such as igneous, metamorphic, or sedimentary rocks, and can contain over 70% iron, with many falling in the 50-60% range.

Combined with other materials like coke and limestone, iron ore is primarily used in steel production. Today, almost all (98%) iron ore is dedicated to steelmaking.

The ore is typically mined in about 50 countries, but Australia, Brazil, China, and India are responsible for 75% of the production.

Because of its essential role in infrastructure development, iron ore is one of the most crucial materials underpinning urbanization and economic growth.

Industrial Metals

Industrial metals occupy the second position on our list, constituting 6.6% of all metals mined in 2022. These metals, including copper, aluminum, lead, and zinc, are employed in construction and industrial applications.

Tiếp tục đọc “All the Metals We Mined in One Visualization”